José Afonso & Filhos has state-of-the-art equipment allowing it to have an optimal response in its productive capacity to face ever more demanding challenges and still having the capacity of taking advantage of new business opportunities that might emerge.

The production process is divided into three units:

- Sawing of wood

- Pellets Factory

- Fábrica de briquetes

|

Sawing of wood |

Pellets |

Briquetes |

Sawing of wood

Wood Type

The wood that we saw is solely maritime pine “pinus pinaster”.

Stock

We have a stock of quantity and quality of pine logs, which allows us to respond swiftly to the different orders we get.

Purpose

Our wood serves different purposes of which we emphasize the pallet wood assemblage, wood packaging material and construction and building material.

-

Thermal Treatment

Our wood is exposed to a heat treatment HT according to the NIMP15 certification.

-

Chemical Treatment

After the thermal treatment, our wood is treated with a chemical preservative to improve its durability.

|

Lumber for Construction |

Sawn Wood for pallets and packaging |

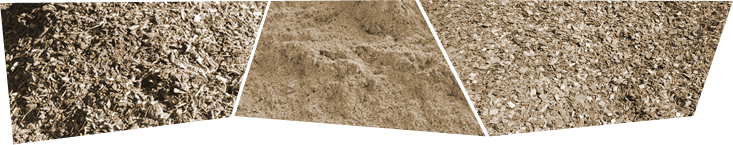

BYPRODUCTS

From the process of cutting and sawing wood, we obtain a number of byproducts, which can have a number of different uses, like raw material for other industries, or from an ecological point of view, as fertilizers and energy provider, among others.

|

Bark |

Sawdust |

Woodchips |

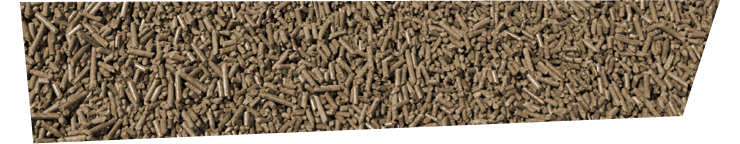

PELLETS

Nova Lenha pellets are solely manufactured out of clean pine (sawdust/chips) with no addition of additives resulting thus in a 100% natural product. By selecting mainly only sawdust from our sawmill we can guarantee that the quality requirements are met.

- Heat power: 4.700 Kcal/Kg, 18 Kj/Kg

- Residues: minimum residual ash, 0,50 %

- Moisture: minimum value, 6% a 7%

- Components: Pure Pinewood 100%, compressed with no additives

- Storage: Unlimited (Protect from humidity)

Instructions for use:

Burn in intended wood pellet stoves following the manufacturer’s recommendations.

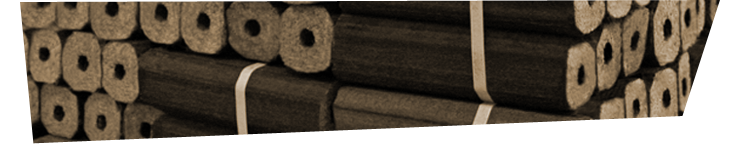

WOOD BRIQUETTES

“Nova Lenha” wood briquettes are of Pinikay type.

Here we refer to octahedron, compact, high-density blocks of briquettes with a central hole in them.

These briquettes are 100% of pure pinewood sawdust, with very low moisture levels. They are compacted by a mechanical press, which allows obtaining high-pressure compaction with no need of additive substances.

- Heat power: Approx. 4.500 Kcal/Kg

- Residues: After combustion, 3 %

- Moisture: Almost none, 5% to 7%

- Components: Compressed 100 % vegetal wood

- Storage: Unlimited (Protect from humidity)

Instructions for use: Like traditional wood.

Briquettes are use in fireplaces, heat recovery units, ovens, wood stoves, boilers, heaters, barbeques and others.

Although similar to traditional wood, it has a superior calorific power, which must be taken into consideration to avoid overheating.